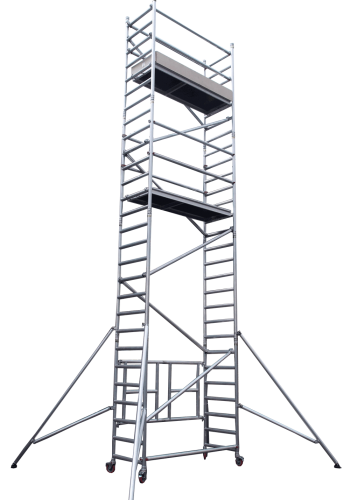

Our range of aluminium scaffold towers includes models suitable for both industrial and home DIY use… and includes leading brands such as BoSS Towers, ZARGES ‘Reachmaster’ ,YOUNGMAN ‘Minimax’ and TELETOWER telescopic towers. Most of our tower systems are available for delivery free of charge direct from the factory to your site within a few days and represent the finest systems currently available in the UK. If you are unsure of which system will suit your needs best, our friendly, knowledgeable staff will be happy to talk you through the options and advise on the most suitable tower for your needs.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Manufactured under ISO 9001:2008

- Made from 2″ 16 gauge aluminium tube

- Folds away flat for ease of storage & transport

- Fits through standard doorways & corridors at 775mm wide

- Folding base unit suitable for single person assembly

- 250mm rung spacing

- Maximum platform safe working load of 275kg, the same as our industrial towers

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Manufactured under ISO 9001:2008

- Made from 2″ 16 gauge aluminium tube

- Folds away flat for ease of storage & transport

- Fits through standard doorways & corridors at 775mm wide

- Folding base unit suitable for single person assembly

- 250mm rung spacing

- Maximum platform safe working load of 275kg, the same as our industrial towers

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Frame horizontals have 500mm spacing and ribbed tubing for increased grip.

- Robotic welding and tube-to-tube joint technology reducing frame weight. (no castings)

- Double trigger action locking claws, enables ease of use when assembling braces.

- Integral ladder system for safe fast access to working platforms.

- Floating frame spigots to aid frame assembly and dismantling.

- Conforms to BS EN 1004 2020

- Manufactured under ISO 9001:2008

- Made from 2″ 16 gauge aluminium tube

- Folds away flat for ease of storage & transport

- Fits through standard doorways & corridors at 775mm wide

- Folding base unit suitable for single person assembly

- 250mm rung spacing

- Maximum platform safe working load of 275kg, the same as our industrial towers

- 2 x short and 2 x long toe boards for Minimax tower platforms

- Quick interlocking design

- Long toe board length 1775mm

- Short toeboard length 754mm

- Weight : 6.6kg

- Industry leading Minimax design and UK quality manufacture… delivered direct from Werner within 5 – 7 working days.

- 4 x SP7 Fixed length stabilisers for Minimax towers up to 3.7m platform height.

- Quick action clamping system

- Closed length 2.3m

- Weight of each stabiliser 3.8kg

- Features large rubber anti-slip shoes

Industry leading design and UK quality manufacture… delivered direct within 5 – 7 working days.

One horizontal brace to create a secure guardrail system when combined with the Minimax folding base unit.

- Quick action locking claws

- Length of each brace 1.83m

- Weight of each brace 1.8kg

- All aluminium construction

- 2 x 2.0m (8 rung) frames

- 1 x Trapdoor deck

- 2 x Diagonal Braces

- 4 x Horizontal Braces

Industry leading design and UK quality manufacture… delivered direct within 5 – 7 working days.

SUBSCRIBE TO OUR NEWSLETTER

Sign up to our newsletter to receive news on product releases, updates and specials!

Our range of aluminium scaffold towers includes models suitable for both industrial and home DIY use… and includes leading brands such as BoSS Towers, ZARGES ‘Reachmaster’ ,YOUNGMAN ‘Minimax’ and TELETOWER telescopic towers. Most of our tower systems are available for delivery free of charge direct from the factory to your site within a few days and represent the finest systems currently available in the UK. If you are unsure of which system will suit your needs best, our friendly, knowledgeable staff will be happy to talk you through the options and advise on the most suitable tower for your needs.

Werner 'BOSS Solo 700' One-Man Alloy Tower 4.2m Working Height (2.2m Platform Height)

Werner 'BOSS Solo 700' One-Man Alloy Tower 4.2m Working Height (2.2m Platform Height)  Minimax 2 Rung Guardrail Pack

Minimax 2 Rung Guardrail Pack  Zarges PAX Tower 3.6m Working Height

Zarges PAX Tower 3.6m Working Height  Minimax Alloy Tower 1.7m Platform height

Minimax Alloy Tower 1.7m Platform height